8 Year Exporter Hp Grade Graphite Electrode - HP Graphite Electrodes For Steel Making – Qifeng

8 Year Exporter Hp Grade Graphite Electrode - HP Graphite Electrodes For Steel Making – Qifeng Detail:

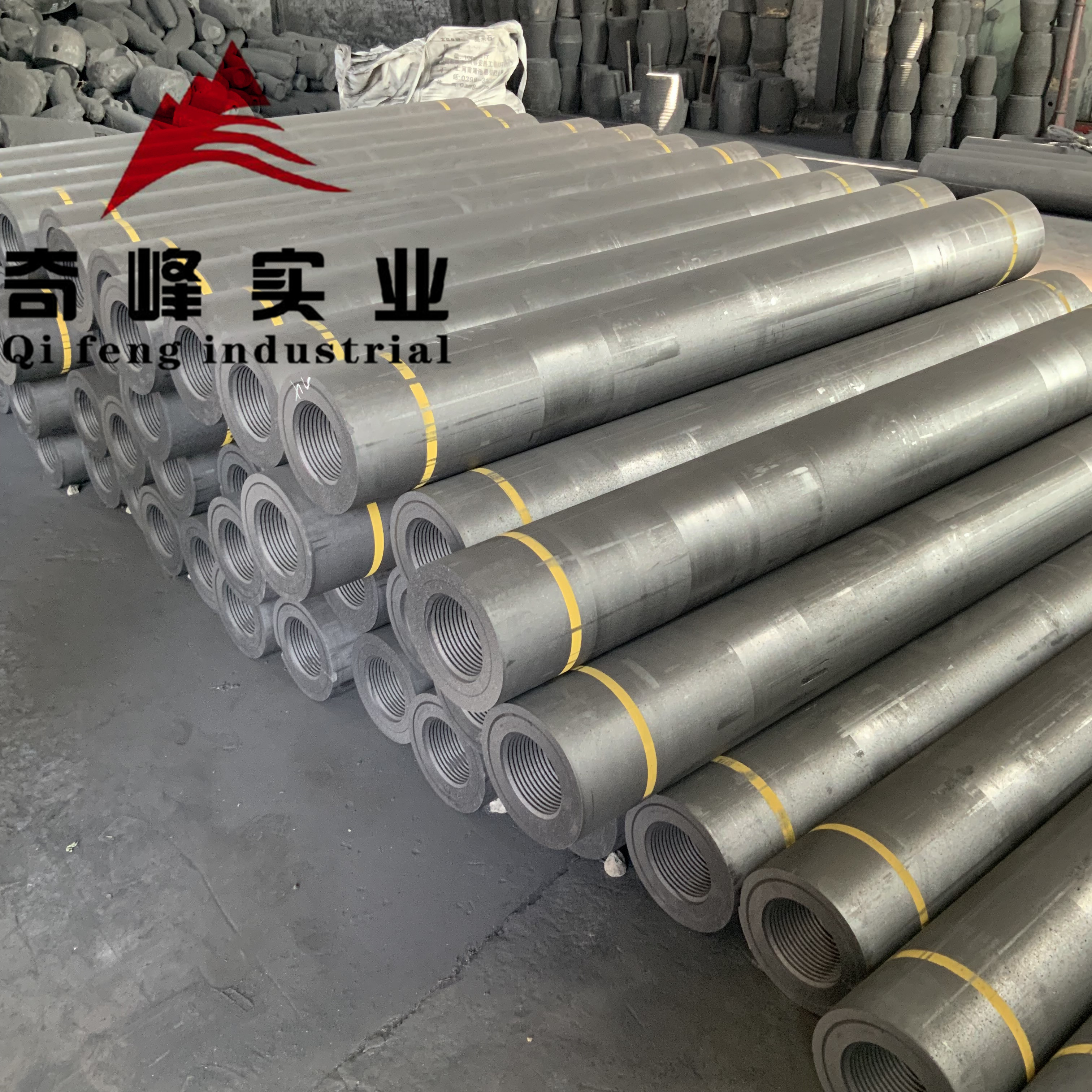

Quick Details:

Place of Origin: Hebei, China (Mainland)

Brand Name: QF

Type: Electrode Block

Application: Steel Making/Smelting Steel

Length: 1600~2800mm

Grade: HP

Resistance (μΩ.m): <6.2

Apparent Density (g/cm³ ): >1.67

Thermal Expansion(100-600℃) x 10-6/℃: <2.0

Flexural Strength (Mpa): >10.5

ASH: 0.3% max

Nipple type: 3TPI/4TPI/4TPIL

Raw Material: Needle Petroleum Coke

Superiority: Low Consumption Rate

Color: Black Gray

Diameter:300mm, 400mm, 450mm, 500mm, 600mm, 650mm, 700mm

Supply Ability

3000 Ton/Tons per Month

Packing And Delivery

Packaging Details:

Standard wooden pallets or according to customer’s requirement.

Port:Tianjin Port

Advantage

(1) the advantages of graphite electrode are easier processing, high discharge machining removal rate, graphite loss is small, therefore, some group based spark machine customers gave up the copper electrode and instead of graphite electrode.In addition, some of the special shape of the electrode can not be made of copper, but graphite is easier to shape, and the copper electrode is heavy, not suitable for processing large electrode, these factors have caused some group based spark machine customer application of graphite electrode.

(2) graphite electrode is easier to process, and the processing speed is obviously faster than copper electrode.For example, graphite is processed by milling process, which is 2-3 times faster than other metals and does not require additional manual processing, while copper electrode needs manual grinding.Similarly, if you use a high-speed graphite processing center to make the electrode, it will be faster and more efficient, and there will be no dust problem.In these processes, the selection of suitable hardness tools and graphite can reduce tool wear and copper electrode damage.When comparing the milling time between the graphite electrode and the copper electrode, the graphite electrode is 67% faster than the copper electrode. In the discharge machining under general conditions, the processing time with the graphite electrode is 58% faster than that with the copper electrode.As a result, processing time is greatly reduced and manufacturing costs are reduced.

(3) the design of graphite electrode is different from that of traditional copper electrode.Many die factory usually in the copper electrode rough processing and finishing aspects have different reserved amount, and graphite electrode is used almost the same reserved amount, which reduces the CAD/CAM and machine processing times, for this reason alone, is enough to greatly improve the precision of mold cavity.

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for 8 Year Exporter Hp Grade Graphite Electrode - HP Graphite Electrodes For Steel Making – Qifeng, The product will supply to all over the world, such as: Melbourne, Bangkok, moldova, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.