At present, the main measures to reduce electrode consumption are:

Optimize power supply system parameters. Power supply parameters are the key factors affecting electrode consumption. For example, for a 60t furnace, when the secondary side voltage is 410V and the current is 23kA, the front-end electrode consumption can be minimized.

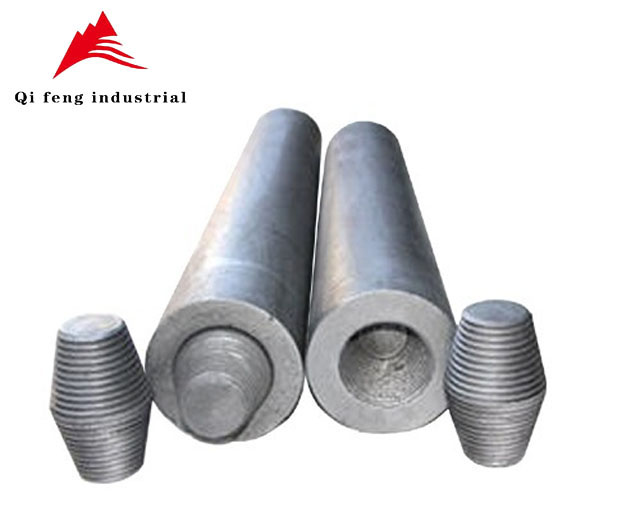

Water-cooled composite electrode is adopted.Water-cooled composite electrode is a new type of electrode developed abroad in recent years. The water-cooled composite electrode is composed of the upper water-cooled steel tube section and the lower graphite working section, and the water-cooled section accounts for about 1/3 of the length of the electrode. Since there is no high temperature oxidation (graphite oxidation) in the water-cooled steel tube section, the electrode oxidation is reduced, and the water-cooled steel tube section maintains good contact with the gripper. Since the thread of water-cooled section and graphite section adopts water-cooled type, its shape is stable, without damage, and can withstand large torque, which improves the strength of the electrode interface, thus significantly reducing the electrode consumption.

Anti - oxidation mechanism of water spray graphite electrode is adopted. In view of the consumption of electrodes in the smelting process, the technical measures of graphite electrode water spraying and oxidation prevention are adopted, that is to say, ring water spraying device is adopted below the electrode griper to spray water on the electrode surface, so that water flows down the electrode surface, and ring pipe is used to blow compressed air to the current surface above the electrode hole of the furnace cover, so as to atomize the water flow. Using this method, the consumption of ton steel electrode decreased obviously. The new technology is first applied in ultra-high power electric furnace. The water spraying electrode method is simple, easy to operate and safe.

Electrode surface coating technology. Electrode coating technology is a simple and effective method to reduce electrode consumption.

The commonly used electrode coating materials are aluminum and various ceramic materials, which have strong oxidation resistance at high temperature and can effectively reduce the oxidation consumption on the electrode side surface.

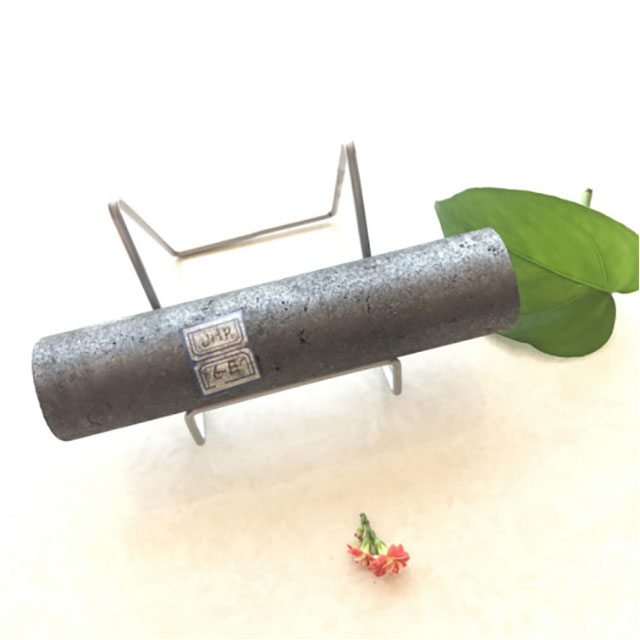

Dip electrode is used. The dip electrode is to dip the electrode into the chemical agent and make the surface of the electrode interact with the agent to improve the resistance of the electrode to high temperature oxidation. The electrode consumption is reduced by 10% ~ 15% compared with the normal electrode.

Post time: Aug-10-2020