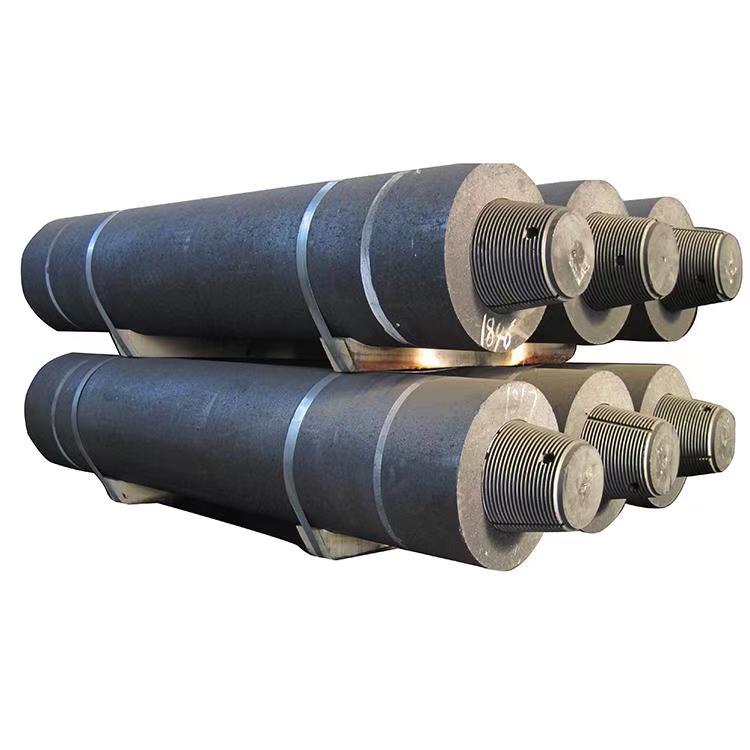

The working principle of ultra-high power (UHP) graphite electrodes is primarily based on the arc discharge phenomenon. Leveraging their exceptional electrical conductivity, high-temperature resistance, and mechanical properties, these electrodes enable efficient conversion of electrical energy into thermal energy within high-temperature smelting environments, thereby driving the metallurgical process. Below is a detailed analysis of their core operational mechanisms:

1. Arc Discharge and Electrical-to-Thermal Energy Conversion

1.1 Arc Formation Mechanism

When UHP graphite electrodes are integrated into smelting equipment (e.g., electric arc furnaces), they act as conductive media. High-voltage discharge generates an electric arc between the electrode tip and the furnace charge (e.g., scrap steel, iron ore). This arc consists of a conductive plasma channel formed by gas ionization, with temperatures exceeding 3000°C—far surpassing conventional combustion temperatures.

1.2 Efficient Energy Transmission

The intense heat generated by the arc directly melts the furnace charge. The electrodes’ superior electrical conductivity (with resistivity as low as 6–8 μΩ·m) ensures minimal energy loss during transmission, optimizing power utilization. In electric arc furnace (EAF) steelmaking, for instance, UHP electrodes can reduce smelting cycles by over 30%, significantly enhancing productivity.

2. Material Properties and Performance Assurance

2.1 High-Temperature Structural Stability

The electrodes’ high-temperature resilience stems from their crystalline structure: layered carbon atoms form a covalent bond network via sp² hybridization, with interlayer binding through van der Waals forces. This structure retains mechanical strength at 3000°C and offers exceptional thermal shock resistance (withstanding temperature fluctuations of up to 500°C/min), outperforming metallic electrodes.

2.2 Resistance to Thermal Expansion and Creep

UHP electrodes exhibit a low coefficient of thermal expansion (1.2×10⁻⁶/°C), minimizing dimensional changes at elevated temperatures and preventing crack formation due to thermal stress. Their creep resistance (ability to resist plastic deformation under high temperatures) is optimized through needle coke raw material selection and advanced graphitization processes, ensuring dimensional stability during prolonged high-load operation.

2.3 Oxidation and Corrosion Resistance

By incorporating antioxidants (e.g., borides, silicides) and applying surface coatings, the electrodes’ oxidation initiation temperature is elevated above 800°C. Chemical inertness against molten slag during smelting mitigates excessive electrode consumption, extending service life to 2–3 times that of conventional electrodes.

3. Process Compatibility and System Optimization

3.1 Current Density and Power Capacity

UHP electrodes support current densities exceeding 50 A/cm². When paired with high-capacity transformers (e.g., 100 MVA), they enable single-furnace power inputs exceeding 100 MW. This design accelerates thermal input rates during smelting—for example, reducing energy consumption per ton of silicon in ferrosilicon production to below 8000 kWh.

3.2 Dynamic Response and Process Control

Modern smelting systems employ Smart Electrode Regulators (SERs) to continuously monitor electrode position, current fluctuations, and arc length, maintaining electrode consumption rates within 1.5–2.0 kg/t steel. Coupled with furnace atmosphere monitoring (e.g., CO/CO₂ ratios), this optimizes electrode-charge coupling efficiency.

3.3 System Synergy and Energy Efficiency Enhancement

Deploying UHP electrodes requires supporting infrastructure, including high-voltage power supply systems (e.g., 110 kV direct connections), water-cooled cables, and efficient dust collection units. Waste heat recovery technologies (e.g., electric arc furnace off-gas cogeneration) elevate overall energy efficiency to over 60%, enabling cascading energy utilization.

This translation maintains technical precision while adhering to academic/industrial terminology conventions, ensuring clarity for specialized audiences.

Post time: May-06-2025