A) used in hot processing mold

Graphite lubricating powder can be used in glass casting, metal casting hot processing mold on the lubricant, role: make the casting more easy to demoulding, and make the workpiece quality better, prolong the service life of the mold.

B) Cooling fluid

Metal cutting lubrication coolant plus a small amount of colloidal graphite lubrication powder is beneficial to improve the processing speed, make the product quality better, prolong the service life of the tool.

C) Precision machinery

Graphite lubricants can also be used on rotating or sliding parts of tightly fitting precision instruments.

D) bearings , mechanical engineering

Rotating and sliding parts of various machines.

High temperature, high load sliding bearings.

E) It is suitable for cold and hot processing of pipe and rod, metal wire drawing extrusion, die forging, stamping and so on.

F) Graphite powder is also suitable for steam engines, internal combustion engines, such as lubrication system.

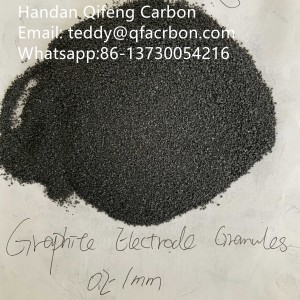

For more details for oue products graphite powder and graphite granules please be free to contact: Email: teddy@qfcarbon.com whatsapp/Mob: 86-13730054216

Post time: Apr-28-2021