For different kinds of carbon and graphite electrode products, according to their different uses, there are special use requirements and quality indicators. When considering what kind of raw materials should be used for a certain product, we should first study how to meet these special requirements and quality indicators.

(1) The selection of raw materials for conducting graphite electrode used in electrometallurgical process such as EAF steelmaking.

The conductive graphite electrode used in electrometallurgical process such as EAF steelmaking must have good conductivity, proper mechanical strength, good resistance to quenching and heating at high temperature, corrosion resistance and low impurity content.

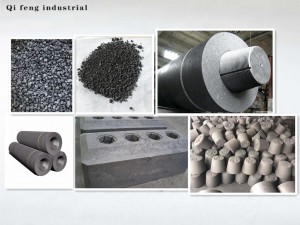

① High quality graphite electrodes are produced from petroleum coke, pitch coke and other low ash raw materials. However, the production of graphite electrode needs more equipment, long process flow and complicated technology, and the power consumption of 1 t graphite electrode is 6000 ~ 7000 kW · H.

② High quality anthracite or metallurgical coke is used as raw material to produce carbon electrode. The production of carbon electrode does not need graphitization equipment, and other production processes are the same as the production of graphite electrode. The conductivity of carbon electrode is much worse than that of graphite electrode. The resistivity of carbon electrode is generally 2-3 times higher than that of graphite electrode. The ash content varies with the quality of raw materials, which is about 10%. But after special cleaning, the ash content of anthracite can be reduced to less than 5%. The ash content of the product can be reduced to about 1.0% if the product is further graphitized. Carbon electrode can be used for smelting common EAF steel and ferroalloy

③ Using natural graphite as raw material, natural graphite electrode was produced. Natural graphite can only be used after being carefully selected and its ash content reduced. The resistivity of natural graphite electrode is about twice that of graphitized electrode. But the mechanical strength is relatively low, easy to break when using. In the area with abundant natural graphite production, natural graphite electrode can be produced to supply small EAF to smelt common EAF steel. When using natural graphite to produce conductive electrode, the equipment and technology are easy to solve and master.

④ Graphite electrode is used to produce regenerated electrode (or graphitized broken electrode) through crushing and grinding of cutting debris or waste products. The ash content of the product is not high (about 1%), and its conductivity is worse than that of the graphitized electrode. Its resistivity is about 1.5 times of that of the graphitized electrode, but its application effect is better than that of the natural graphite electrode. Although it is easy to master the technology and the equipment to produce regenerated electrode, the raw material source of graphitization is limited, so this way is not the development direction.

Post time: Jun-11-2021