Calcined coke is a kind of carburizer and petroleum coke of various specifications.

The main specifications of graphite products are ¢150-¢1578 and other models. It is indispensable for iron and steel enterprises, industrial silicon polysilicon enterprises, emery enterprises, aerospace materials industry and other products.

1: Petroleum coke

Petroleum coke is a black or dark gray hard solid petroleum product with a metallic luster and is porous. It is a granular, columnar, or needle-like carbonaceous material consisting of microscopic graphite crystals.

Petroleum coke consists of hydrocarbons, 90-97% carbon, 1.5-8% hydrogen, nitrogen, chlorine, sulfur, and heavy metal compounds.

Petroleum coke is the by-product of the pyrolysis of raw oil in delayed coking unit to produce light oil at high temperature.

The output of petroleum coke is about 25-30% of that of raw oil.

Its low calorific value is about 1.5-2 times of coal, ash content is no more than 0.5%, volatile content is about 11%, and its quality is close to anthracite.

2: Quality standard of petroleum coke Delayed petroleum coke refers to coke produced by delayed coking unit, also known as ordinary coke, there is no corresponding ## standard.

At present, domestic production enterprises mainly produce according to the industry standard SH0527-92 formulated by the former China Petrochemical Corporation.

The standard is mainly classified according to the sulfur content of petroleum coke.

No. 1 coke is suitable for making ordinary power graphite electrode in steelmaking industry, and also used as carbon for aluminum refining

No. 2 coke is used for electrode paste and graphite electrode production in electrolytic cell (furnace) in aluminum smelting industry

No. 3 coke is used in the production of silicon carbide (grinding material) and calcium carbide (calcium carbide), as well as other carbon products, as well as in the production of anode blocks for aluminum smelter and in the construction of carbon lining bricks or furnace bottom in blast furnace.

3: the main USES of petroleum coke

The main USES of petroleum coke are pre-baked anode and anode paste for electrolytic aluminum, carbon production of carbonizing agent, graphite electrode, smelting industrial silicon and fuel, etc.

According to the structure and appearance of petroleum coke, petroleum coke products can be divided into needle coke, sponge coke, projectile coke and powder coke:

(1) Needle-shaped coke, with obvious needle-like structure and fiber texture, is mainly used as high-power graphite electrode and ultra-high-power graphite electrode in steelmaking.

Because needle coke has strict quality index requirements in sulfur content, ash content, volatiles content and true density, there are special requirements on the production technology and raw materials of needle coke.

(2) Sponge coke, with high chemical reactivity and low impurity content, is mainly used in aluminum smelting industry and carbon industry.

(3) Projectile coke or spherical coke: it is spherical in shape and 0.6-30mm in diameter. It is generally produced from high-sulfur and high-asphaltene residue and can only be used for power generation, cement and other industrial fuels.

(4) Powder coke: it is produced by fluidized coking process with fine particles (diameter: 0.1-0.4mm), high volatilization content and high thermal expansion coefficient, so it cannot be directly used in electrode preparation and carbon industry.

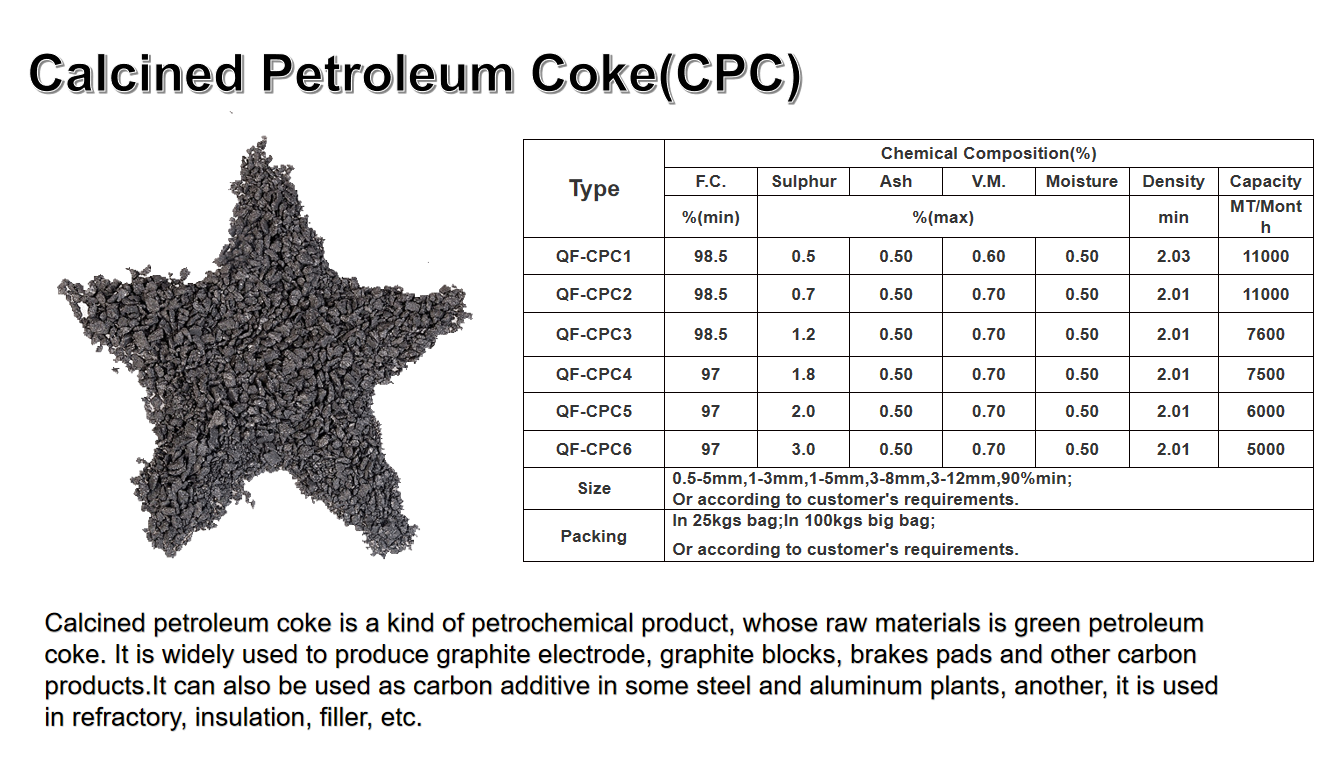

4: Calcined petroleum coke

When the graphite electrode for steelmaking or the anode paste (melting electrode) for aluminum and magnesium, in order to make petroleum coke (coke) meet the requirements, the coke must be calcined.

The calcining temperature is generally around 1300℃, the purpose of which is to get rid of the naphthol coke volatilization as far as possible.

In this way, the hydrogen content of petroleum coke reproducts can be reduced, the graphitization degree of petroleum coke can be improved, the high-temperature strength and heat resistance of graphite electrode can be improved, and the electrical conductivity of graphite electrode can be improved.

Calcining is mainly used to produce graphite electrode, carbon paste products, Diamond sand, food-grade phosphorus industry, metallurgical industry and calcium carbide, among which graphite electrode is widely used.

Coke without forging can be directly used as calcium carbide, silicon carbide and boron carbide as grinding materials.

It can also be directly used as coke for metallurgical industry blast furnace or blast furnace lining carbon brick, also can be used for casting process compact coke, etc.

Post time: Nov-20-2020